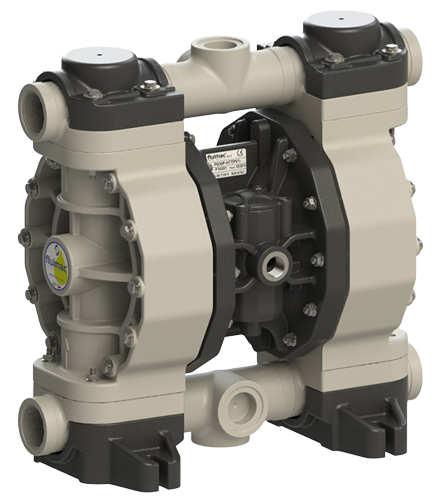

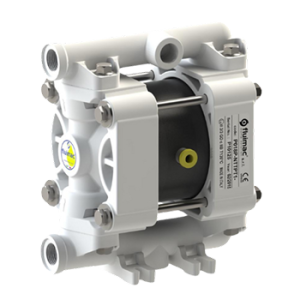

Designed for Operators. Trusted by Engineers.

Most AODD pumps are noisy, shaky, and high-maintenance. But the Phoenix is different.

Operators love it for how quiet and vibration-free it is—no shouting over the pump or chasing down loose fittings.

Engineers trust it because it runs reliably even under low air pressure, without the stalling issues other pumps face.

Owners choose it because it reduces downtime and replacement costs over time.

Whether you're running chemicals, slurry, or wastewater—the Phoenix delivers smooth, confident flow that feels like a premium upgrade to your entire system.

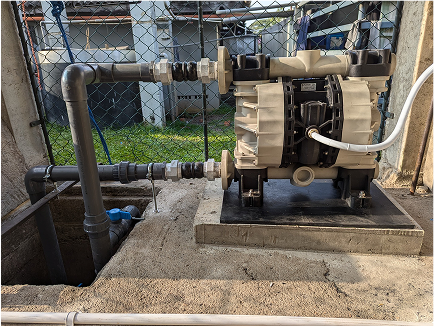

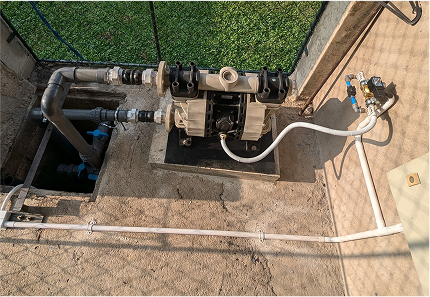

Installed Across Malaysia in Facilities That Can’t Afford Downtime

Chemical Plants

Wastewater Treatment Skids

Semiconductor Lines

Fertigation Back-ends

Manufacturing Floors

“It’s so quiet we had to walk over to check if it was running.”

Trusted Across Industries

Low Noise

"I can talk to my colleagues without shouting and hurting my throat."

Low Noise

"I can talk to my colleagues without shouting and hurting my throat."

Good Performance Noise

"Still pumping while others stop when air pressure drops."

Low Maintenance

"I'm telling the engineers to get more of this pump because it does not bother me much."

Easy Maintenance

"4 screws, one knock, and the air valve’s out. Even a kid can do it."

What Makes the Phoenix So Smooth and Reliable?

Non-Stalling, Non-Freezing Air Valve

The advanced air system is fully lube-free, designed with an unbalanced pilot spool and an acetalic shuttle that prevent icing, jamming, or dead zones—ensuring consistent starts and uninterrupted flow, even in low air pressure conditions.

Whisper-Quiet Operation

Phoenix is one of the quietest AODD pumps in its class—thanks to a double silencer exhaust system and precision-balanced air path that reduces harsh discharge noise and resonance. Operators no longer need to shout or second-guess whether the pump is running.

Non-Stalling, Non-Freezing Air Valve

The advanced air system is fully lube-free, designed with an unbalanced pilot spool and an acetalic shuttle that prevent icing, jamming, or dead zones—ensuring consistent starts and uninterrupted flow, even in low air pressure conditions.

Easy, Tool-Free Maintenance

The air exchange kit is externally accessible, requiring just four screws to service. No full teardown or special tools needed—minimizing downtime and keeping your maintenance team happy.

Durable, Long-Life Diaphragm Design

Phoenix uses a pinch-clamp diaphragm mounting system that distributes stress more evenly, extending diaphragm life while improving chemical sealing and leak resistance.

Versatile & Rugged Performance

Handles abrasives, slurries, solvents, and viscous fluids up to 55,000 cps. Fully self-priming, submersible, and deadhead safe—built to perform under the toughest plant conditions.

Specifications

Size

1/4″ to 3″

Body Material

PP, PVDF, Aluminium, SS316

Diaphragm Material

PTFE, Santoprene, Hytrel, EPDM, NBR

Connection Type

BSP Threaded, Flanged, NPT Threaded, Tri-Clamp

Where It Fits

Chemical Plants

Wastewater Treatment Skids

Semiconductor Lines

Manufacturing Floors

Chemical Plants

Wastewater Treatment Skids

Semiconductor Lines

Choose the Quietest AODD Pump in Malaysia That Fits Your Flow

Tell us your water flow, chemical, and system goal—we’ll help you find the right match.